Flexible-Disc-Coupling

flexible disc coupling

- An actual limited end float design

- A zero-backlash design

- High-speed rating and balance

- Finds use on fractional to 100,000 hp drives

Application: Hydrostatic application (Gearbox to hydraulic pump), turbomachinery, blower, compressor, mixer, servo motor applications, stepper motors, high-speed machine tools, semiconductor manufacturing equipment, actuator, surface chip mounting, and packaging machine.

Main Products

Couplings are devices used to connect two shafts together and are divided into two categories: Rigid and Flexible.

Flexible Disc Servo Couplings

These couplings are especially designed for precision instruments, encoder drives, robotics, aircraft equipment, radar, laser, mechanical devices, computers, precision remote controls. UNEQUALED PERFORMANCE.Some of the features are: Zero backlash. Low inertia. Handles offset and angular misalignment. Torsional rigidity. Uniform velocity. No friction, wear, or lubrication. Long life. Low side loads on bearings. Accurate concentricity. Unaffected by dust or corrosive atmosphere. Available in four O.D. sizes, and any bore in inch or metric.

Single Flex Composite Disc Couplings

Single-flex Composite Disc Couplings (Couplings) deliver high torsional stiffness, precision, and durability in demanding servo motor applications. These compact couplings feature a single composite disc and a zero-backlash design to provide smooth and accurate operation at any speed, including high-speed reversing applications. Single flex couplings accommodate angular, axial, and parallel misalignment and eliminate issues related to fatigue and fretting seen with metal disc couplings.

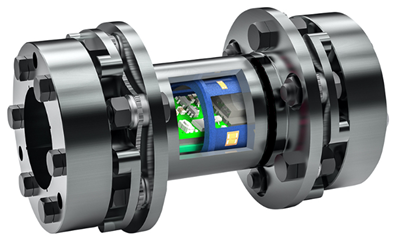

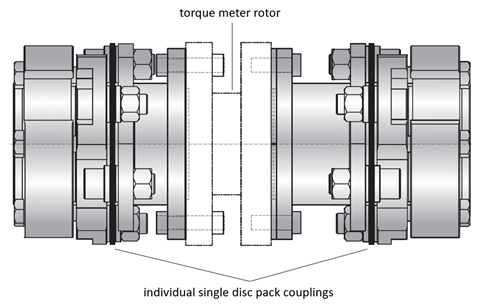

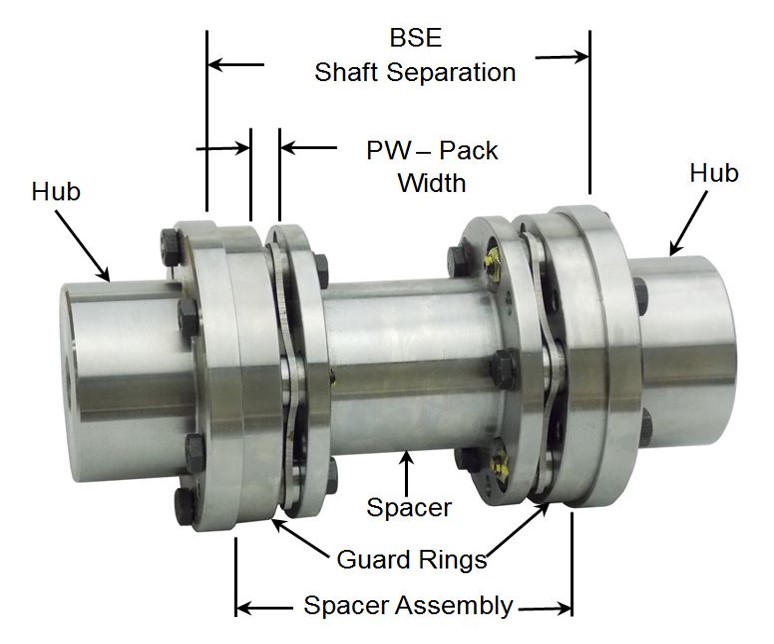

Composite Disc Floating Shaft Couplings

Floating shaft couplings, also called spacer couplings, are designed for applications where drive and load components are spaced far apart. These zero-backlash and torsionally stiff solutions provide superior misalignment capacity and can be made to any length requirement. Composite disc couplings provide very low reaction loads and are excellent for reversing applications. We offer flexible floating shaft composite disc couplings in a broad range of bore sizes and torque ratings, making it easy to find the right fit for your application.

Custom Designs

Flexible Disc Coupling Precautions:

(2)Flexible disc couplings are non-lubricated, so maintenance is not required to re-lubricate the coupling assembly. Since there is no lubricant, flexible disc couplings avoid the mess that can result from maintaining or running a greased coupling.

(3) Flexible disc couplings can be designed with relatively tight tolerances to provide a well balanced coupling assembly. A well balanced coupling has a low magnitude of imbalance.

(4) Imbalance is inherent in every coupling assembly. The imbalance will create a radial force when the coupling is rotated. The magnitude of the force increases as the rotating speed (RPM) increases. The relationship of the radial force to the rotating speed is a squared function. In other words, doubling the speed results in four times the radial force, and tripling the speed results in nine times the radial force.

(5) In the unlikely event of a fracture, flexible disc couplings are generally expected to fracture in a progressive manner beginning at the outer disc of the disc pack. When this occurs, the coupling will run and perform with almost no loss of function. The fracture may eventually progress into the subsequent discs. Most often the progression of the fractures becomes evident during a visual inspection. Alternately, there would be a noticeable increase in vibration. In critical applications, a vibration sensor can be used to automatically shut down the equipment.

(6) Flexible disc couplings may be visually inspected to observe the flexible disc and hardware by removing the guard and observing the components. This inspection is best performed when the rotation is stopped and the guard is removed. A strobe light can be used to inspect a rotating coupling, and care should be exercised and safety should be evaluated before approaching any rotating assembly.

Video introduction

Flexible disc packs are comprised of thin sheet metal shims, stamped or laser cut in a ring shape with a series of mounting holes; commonly 6-8 but more or fewer are also used, depending on the size of the coupling, with the smallest commonly using four and with any number of holes for the very most significant sizes.

The shims are stacked together and held in place by bushings, and the resulting disc pack is bolted into the coupling system. Misalignment compensation depends on the flexibility of the shims themselves. Generally, the larger the stack, the greater the overall stiffness of the disc pack in terms of both torsion and bending.

Centering of the disc pack in the coupling can be accomplished by different means. One standard method is precision machined pockets in the adjacent mounting flanges, which hold the disc packs concentrically in place by their bushings. The disc packs are mounted to their respective hubs with the bolted joints alternating between the driving hub and the driven hub.

our service