Product Description

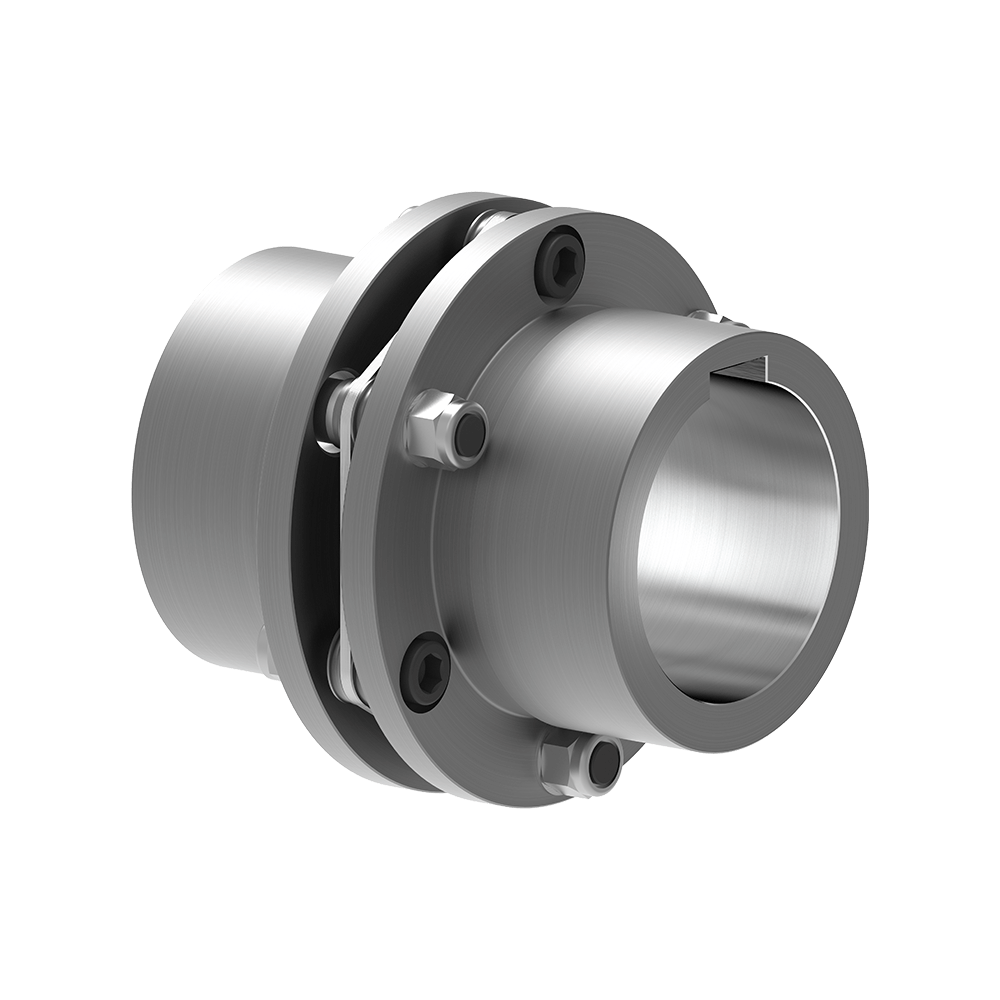

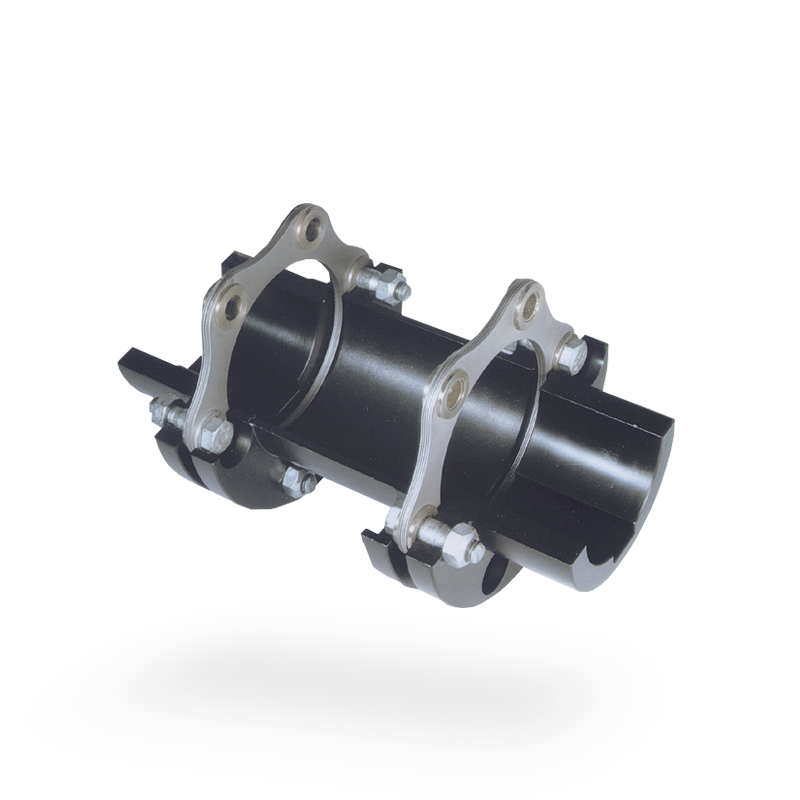

| Product Name | Flexible Diaphragm Coupling Multiple Disc Shaft Coupling Single Double Tubular Coupler | |

| Material | Aluminum Alloy,Stainless Steel | |

| Model NO. | Single Disc | DC26-T1 DC34-T1 DC39-T1 DC44-T1 DC56-T1 DC68-T1 DC82-T1 DC94-T1 DC104-T1 |

| Double Disc | DC26-T2 DC34-T2 DC39-T2 DC44-T2 DC56-T2 DC68-T2 DC82-T2 DC94-T2 DC104-T2 | |

| Structure | Tubular Type | |

| Max Bore Diameter | 10mm-45mm, customized | |

| Min Bore Diameter | 5mm-26mm, customized | |

| Outer Diameter | 26mm-104mm, customized | |

Features

1. One Piece metallic spring coupling

2. Zero backlash

3. Absorption of parallel, angular misalignment and shaft end-play by spring action

4. Identical clockwise and anticlockwise rotational characteristics

5. Setscrew type or Clamp Type

6. Material: Aluminum Alloy or Stainless steel or other materials per customers’ request.

7. Anti-corrsion,widely used in medical science ,chemistry

8. High flexibilty

9. For servomotor stepmotor

Applications

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6. Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

| Packing&Shipping | |

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

About MIGHTY

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in

time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Indicators of Wear or Damage in Disc Couplings

Disc couplings can exhibit signs of wear or damage over time due to factors like misalignment, overloading, or general usage. Detecting these issues early is crucial for preventing further damage. Some common indicators of wear or damage in disc couplings include:

- Vibration: Excessive vibration during operation can signal misalignment, component wear, or imbalance in the disc coupling.

- Noise: Unusual noises like clicking, clanking, or rattling can indicate wear, misalignment, or damage in the coupling components.

- Heat Generation: Excessive heat near the coupling area can suggest friction or misalignment issues.

- Reduced Performance: Decreased efficiency, torque transmission, or system performance may point to coupling wear or damage.

- Visual Inspection: Look for signs of visible wear, corrosion, cracks, or deformation on the coupling components.

To detect these signs of wear or damage, regular visual inspections, vibration analysis, and performance monitoring are essential. Early detection allows for timely maintenance or replacement of the affected components, ensuring the continued reliability and safety of the disc coupling and the machinery it serves.

Recent Advancements in Disc Coupling Design

Disc coupling technology has seen continuous advancements to enhance performance, reliability, and adaptability to various applications. Some recent innovations in disc coupling design include:

- Material Enhancements: The development of new materials, such as advanced alloys and composite materials, has improved coupling durability, corrosion resistance, and overall lifespan.

- Flexible Disc Profiles: Innovative disc profiles are designed to optimize flexibility while maintaining torque transmission capabilities, allowing for better misalignment compensation and shock absorption.

- Modular Designs: Modular disc coupling systems offer flexibility in adapting to different torque and misalignment requirements, making them versatile for a wide range of applications.

- Enhanced Torsional Stiffness: Some designs focus on achieving higher torsional stiffness, ensuring accurate torque transmission and responsiveness even in demanding conditions.

- Smart Couplings: Integration of sensor technology enables real-time monitoring of coupling performance, allowing for predictive maintenance and reducing downtime.

These advancements are driven by the increasing demands of modern machinery and the need for higher efficiency, reduced maintenance, and improved overall system performance. Engineers and manufacturers are continually exploring new ways to optimize disc coupling design for a variety of industries and applications.

Function of Disc Couplings in Torque Transmission and Misalignment Compensation

Disc couplings are designed to transmit torque between two shafts while accommodating various forms of misalignment. The primary components of a disc coupling include two hubs and a flexible disc element made of a resilient material such as stainless steel. Here’s how a disc coupling works to transmit torque and handle misalignment:

- Torque Transmission: When torque is applied to one hub of the disc coupling, it induces angular displacement in the flexible disc. The flexible disc element bends slightly, allowing the torque to be transmitted from one hub to the other. This bending action of the disc results in an elastic deformation, which helps maintain the torque transfer.

- Angular Misalignment Compensation: Disc couplings can accommodate angular misalignment between the two connected shafts. As the hubs are misaligned angularly, the flexible disc element compensates by bending at an angle. The disc’s flexibility and the elastic properties of the material allow it to absorb and accommodate the angular misalignment without transmitting excessive forces to the connected machinery.

- Parallel Misalignment Compensation: In cases of parallel misalignment, where the axes of the two shafts are not perfectly aligned, the disc coupling can also absorb a certain degree of parallel offset. The flexibility of the disc allows for slight axial movement, ensuring that the hubs remain connected even when there’s a minor parallel misalignment.

- Torsional Stiffness: While disc couplings are designed to accommodate misalignment, they also exhibit torsional stiffness. This means that under normal operating conditions, the disc coupling remains rigid enough to efficiently transmit torque between the shafts, minimizing torsional deflection and maintaining the integrity of torque transfer.

The design and material properties of the flexible disc element play a crucial role in determining the coupling’s ability to handle misalignment while transmitting torque effectively. Disc couplings are widely used in various industrial applications where torque transmission and misalignment compensation are critical requirements.

editor by CX 2024-05-09