Product Description

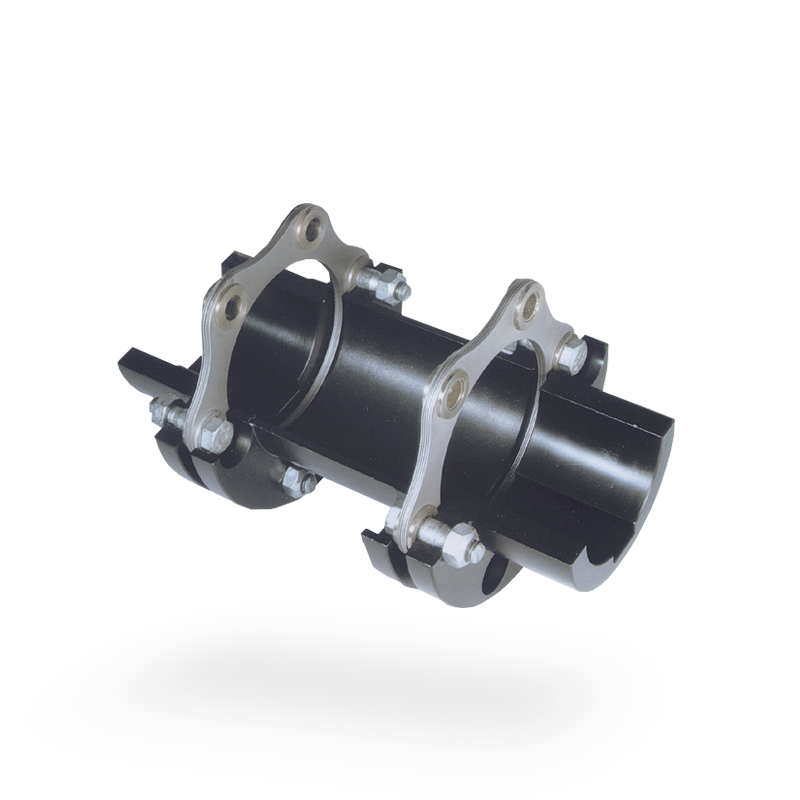

SG7-8 Single plate springs clamp type flexible disc couplings

Product Description

| Item No.: |

|

|||||||

| Features: |

|

|||||||

| Specification: |

|

|||||||

| Application: |

|

|||||||

| Delivery: |

|

|||||||

| Remark: |

|

|||||||

Product Picture

Drawing:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Common Applications of Disc Couplings

Disc couplings find extensive use across various industries and applications where reliable torque transmission, misalignment compensation, and torsional stiffness are essential. Some notable examples include:

- Industrial Machinery: Disc couplings are employed in industrial equipment such as pumps, compressors, generators, and conveyors. They ensure precise torque transfer and alignment in heavy-duty machinery.

- Power Generation: Gas turbines, steam turbines, and power generators often utilize disc couplings to transmit torque between components while withstanding high rotational speeds.

- Aerospace: In aircraft and spacecraft, disc couplings help connect critical systems like engines and auxiliary power units, ensuring dependable torque transmission in demanding environments.

- Marine: Ships and offshore platforms use disc couplings to connect propulsion systems, generators, and other machinery, even in conditions with variable loads and misalignments.

- Oil and Gas: Disc couplings play a crucial role in drilling rigs, pumps, and other equipment where reliable torque transmission and misalignment compensation are vital.

- Automotive: Some automotive applications use disc couplings to connect components within drivetrains and transmissions, especially in vehicles with high-performance requirements.

These examples highlight the versatility and importance of disc couplings in various industries where precise torque transmission, misalignment handling, and torsional stiffness are critical for optimal performance.

Recent Advancements in Disc Coupling Design

Disc coupling technology has seen continuous advancements to enhance performance, reliability, and adaptability to various applications. Some recent innovations in disc coupling design include:

- Material Enhancements: The development of new materials, such as advanced alloys and composite materials, has improved coupling durability, corrosion resistance, and overall lifespan.

- Flexible Disc Profiles: Innovative disc profiles are designed to optimize flexibility while maintaining torque transmission capabilities, allowing for better misalignment compensation and shock absorption.

- Modular Designs: Modular disc coupling systems offer flexibility in adapting to different torque and misalignment requirements, making them versatile for a wide range of applications.

- Enhanced Torsional Stiffness: Some designs focus on achieving higher torsional stiffness, ensuring accurate torque transmission and responsiveness even in demanding conditions.

- Smart Couplings: Integration of sensor technology enables real-time monitoring of coupling performance, allowing for predictive maintenance and reducing downtime.

These advancements are driven by the increasing demands of modern machinery and the need for higher efficiency, reduced maintenance, and improved overall system performance. Engineers and manufacturers are continually exploring new ways to optimize disc coupling design for a variety of industries and applications.

Function of Disc Couplings in Torque Transmission and Misalignment Compensation

Disc couplings are designed to transmit torque between two shafts while accommodating various forms of misalignment. The primary components of a disc coupling include two hubs and a flexible disc element made of a resilient material such as stainless steel. Here’s how a disc coupling works to transmit torque and handle misalignment:

- Torque Transmission: When torque is applied to one hub of the disc coupling, it induces angular displacement in the flexible disc. The flexible disc element bends slightly, allowing the torque to be transmitted from one hub to the other. This bending action of the disc results in an elastic deformation, which helps maintain the torque transfer.

- Angular Misalignment Compensation: Disc couplings can accommodate angular misalignment between the two connected shafts. As the hubs are misaligned angularly, the flexible disc element compensates by bending at an angle. The disc’s flexibility and the elastic properties of the material allow it to absorb and accommodate the angular misalignment without transmitting excessive forces to the connected machinery.

- Parallel Misalignment Compensation: In cases of parallel misalignment, where the axes of the two shafts are not perfectly aligned, the disc coupling can also absorb a certain degree of parallel offset. The flexibility of the disc allows for slight axial movement, ensuring that the hubs remain connected even when there’s a minor parallel misalignment.

- Torsional Stiffness: While disc couplings are designed to accommodate misalignment, they also exhibit torsional stiffness. This means that under normal operating conditions, the disc coupling remains rigid enough to efficiently transmit torque between the shafts, minimizing torsional deflection and maintaining the integrity of torque transfer.

The design and material properties of the flexible disc element play a crucial role in determining the coupling’s ability to handle misalignment while transmitting torque effectively. Disc couplings are widely used in various industrial applications where torque transmission and misalignment compensation are critical requirements.

editor by CX 2024-04-16